Laser Consumables China Manufacturer & Supplier

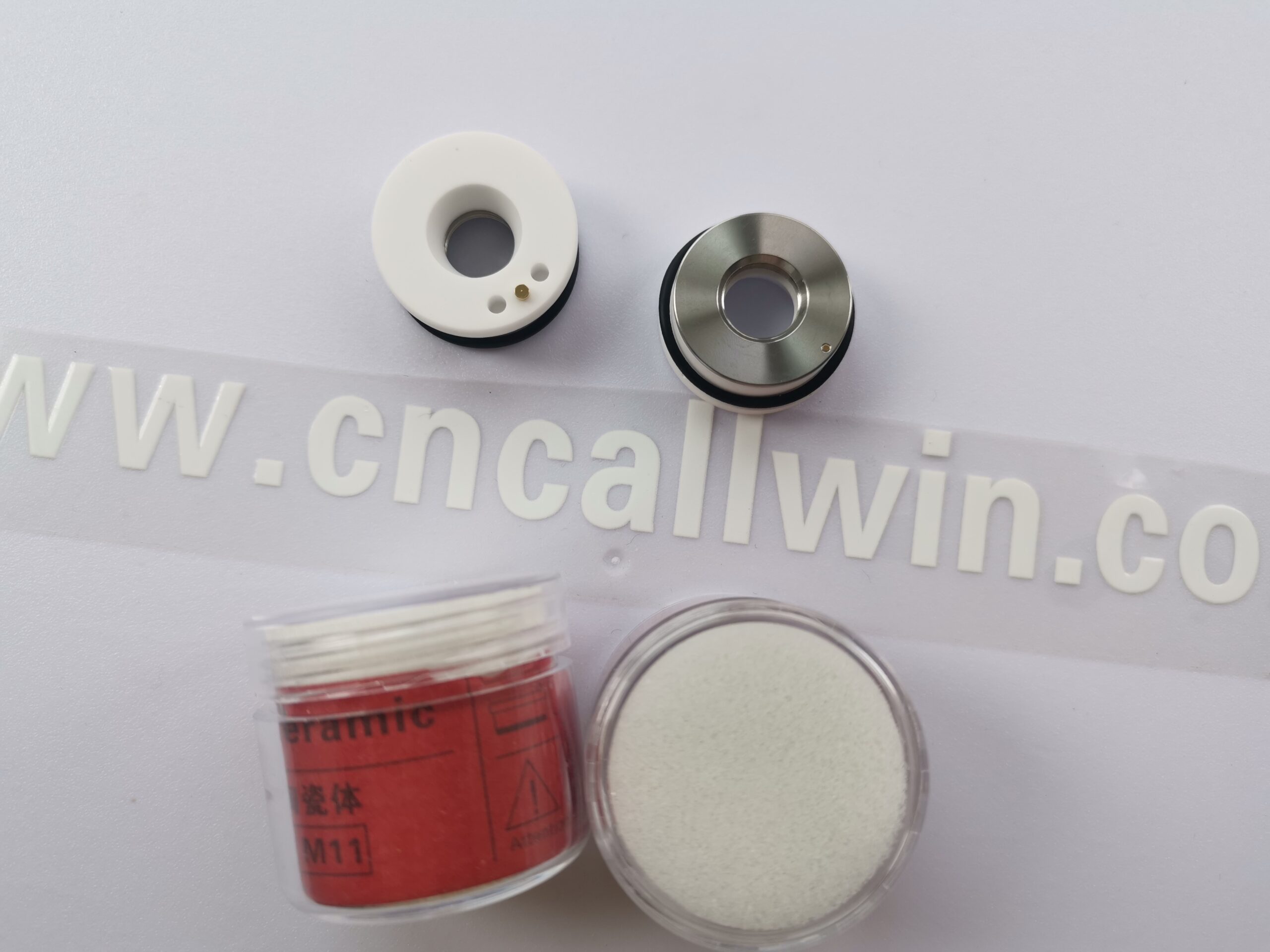

Welcome to Allwin CNC: Your Trusted Source for Laser Cutting Machine Consumables. Enhance the performance and reliability of your laser cutting machine with our premium range of laser spare parts. At Allwin CNC, we specialize in providing top-of-the-line products, including protective mirrors, focusing lenses, collimating lenses, nozzles, ceramic rings, and much more.

Laser Consumables Categories

ABOUT LASER CONSUMABLES

Our laser spares are designed to optimize the efficiency and precision of your laser cutting operations. Whether you’re working with thin metals, thick materials, or intricate designs, our high-quality products ensure consistent and accurate results, every time.

Laser Consumables Videos

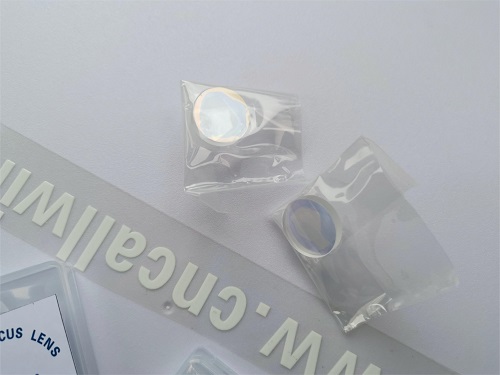

Protective Mirrors: Safeguard your laser cutting machine’s critical components with our durable protective mirrors. Designed to withstand extreme conditions, they effectively shield your optics from debris, heat, and harmful reflections, ensuring optimal beam quality and system longevity.

Focusing Lenses: Achieve impeccable beam control and focus with our advanced focusing lenses. Engineered with precision and durability in mind, our lenses deliver excellent beam stability and enable efficient energy delivery to your cutting point, allowing for precise and clean cuts.

Collimating lenses: Expand your laser beam’s capabilities and versatility with our premium collimating lens. These devices provide adjustable beam diameter, allowing for control over beam divergence and collimation. Achieve superior cutting performance for a wide range of materials, from delicate fabrics to thick metals.

Nozzles: Our high-performance nozzles are designed to optimize laser cutting processes. With precise flow control and efficient material removal, they minimize heat-affected zones and deliver clean, smooth cuts. We provide single-layer and double-layer nozzles for laser cutting machines, as well as various models of nozzles for handheld laser welding machines suitable for brands such as Suplasercut and Ralfer. Choose from a variety of sizes and configurations tailored to your specific application needs.

Ceramic Rings: Ensure thermal stability and longevity in high-power laser cutting operations with our reliable ceramic rings. These durable components offer excellent resistance to thermal shocks, enabling consistent performance even in demanding operating conditions.

At Allwin CNC, we are committed to providing you with exceptional fiber laser consumables that meet the highest industry standards. Our products undergo rigorous testing and quality assurance processes to ensure reliability, compatibility, and cost-effectiveness.

Experience the full potential of your laser cutting machine with our premium range of laser consumables. Explore our comprehensive catalog online and discover how our cutting-edge solutions can elevate your cutting capabilities to new heights. Contact us today to discuss your specific requirements and let us help you achieve unmatched precision and efficiency in laser cutting.

Why Choose Laser Cutting?

There are several reasons why laser cutting is often preferred over other cutting methods. Firstly, laser cutting offers exceptional precision and accuracy. The focused laser beam allows for intricate and detailed cuts, making it ideal for creating complex shapes and designs. This level of precision is challenging to achieve with traditional cutting methods.

Secondly, laser cutting is highly versatile and can be used on a wide range of materials. Whether it’s metal, plastic, wood, fabric, or even glass, laser cutting can provide clean and precise cuts. This versatility makes it a popular choice in various industries, including manufacturing, automotive, aerospace, and signage.

Another advantage of laser cutting is its non-contact nature. The laser beam cuts through the material without physically touching it, which reduces the risk of damage or distortion. This is particularly advantageous when working with delicate materials or materials that are sensitive to heat.

Additionally, laser cutting offers high-speed and efficient operation. The laser beam can cut at incredibly fast speeds, resulting in quicker production cycles and increased productivity. Furthermore, the process can be computer-controlled and automated, ensuring consistent and repeatable cutting results.

Moreover, laser cutting is a relatively clean process. It produces minimal waste since the laser beam vaporizes or melts the material it cuts, leaving behind a narrow kerf. This reduces material waste and enhances cost-effectiveness.

In summary, laser cutting’s key advantages, including precision, versatility, non-contact nature, high-speed operation, and minimal waste production, make it a preferred choice over other cutting methods. Its ability to deliver intricate cuts, work with various materials, and offer efficient operation makes it a valuable tool in many industries.

Why Laser Consumables Require Regular Replacement?

Laser cutting machines are powerful tools that offer precise and efficient cutting capabilities, but they rely on various consumable components. These consumables, including protective mirrors, focusing lenses, nozzles, and others, play a crucial role in the machine’s performance. However, they have relatively shorter lifespans and require timely replacement, ensuring optimal operation and maintaining cutting quality.

Intense Laser Energy:

Laser cutting machines generate highly concentrated and intense laser beams. Over time, this concentrated energy takes a toll on the consumable components, causing degradation and wear.

Exposure to Heat and Debris:

During laser cutting, the consumables are exposed to intense heat, molten material, and often debris. This exposure can lead to thermal stress, thermal shock, and build-up, which affects their performance and lifespan.

Precision is Key:

Laser cutting relies on extreme precision. Even small changes or deterioration in the consumables can result in reduced cutting quality, accuracy, and efficiency. Regular replacement ensures consistent performance and superior cut results.

Optical Clarity:

Protective mirrors and lenses play a vital role in guiding and focusing the laser beam. Over time, these components can accumulate dust, debris, or suffer from surface damage, leading to reduced optical clarity. Regular replacement guarantees clear and accurate beam delivery.

Performance Optimization:

Laser cutting demands high-quality cuts, minimal heat-affected zones, and maximum productivity. By replacing consumables in a timely manner, you ensure that the machine operates at its peak performance, delivering exceptional results.

Cost-Effectiveness:

Though consumables require periodic replacement, it is a cost-effective measure in the long run. Regularly replacing consumables ensures consistent cutting quality, minimizes downtime due to unexpected component failures, and extends the overall lifespan of the machine.

At Allwin CNC, we understand the importance of reliable and durable consumables for laser cutting machines and handheld laser welding machine. Our range of high-quality consumables is designed to withstand the rigorous demands of laser cutting, delivering exceptional performance and longevity.

Ensure the longevity and performance of your laser cutting machine by regularly replacing consumables. Visit our website to explore our comprehensive selection of top-quality consumable components and optimize your laser cutting operations. Trust in our expertise and products to achieve superior cutting precision and efficiency.

Why Choose Our Laser Consumables?

- Superior Quality: We take pride in offering laser cutting machine consumables that are built to the highest standards of quality. Our products undergo rigorous testing and quality assurance processes to ensure optimal performance and reliability.

- Precision and Accuracy: Our spare parts are engineered to provide exceptional precision and accuracy in laser cutting operations. With our products, you can achieve clean, smooth cuts with minimal heat-affected zones, ensuring high-quality results every time.

- Extended Lifespan: We understand the importance of durability and longevity in consumable components. Our products are designed to withstand the intense demands of laser cutting, reducing the frequency of replacements and saving you time and costs in the long run.

- Wide Range of Options: We offer a diverse range of consumables to cater to various laser cutting requirements. Whether you need protective mirrors, focusing lenses, nozzles, or other components, we have the right solution to suit your specific needs.

- Compatibility and Easy Installation: Our consumables are designed to be compatible with a wide range of laser cutting machines. With user-friendly designs and easy installation processes, you can quickly integrate our products into your existing setup.

- Exceptional Customer Support: We believe in providing outstanding customer support throughout your experience with us. Our knowledgeable team is ready to assist you with product selection, technical inquiries, and any other assistance you may need.

- Cost-Effective Solutions: We offer competitive pricing for our high-quality consumables, ensuring that you receive excellent value for your investment. Our products are designed to deliver long-term cost savings by optimizing performance and reducing downtime.

Choose our company for reliable and top-quality laser cutting machine consumables. With our products, you can maximize your machine’s performance, achieve superior cutting results, and enhance your overall productivity. Trust in our expertise and dedication to delivering excellence in laser cutting consumables.

Contact us today to explore our extensive range of consumable options and experience the difference our products can make in your laser cutting operations.