Others

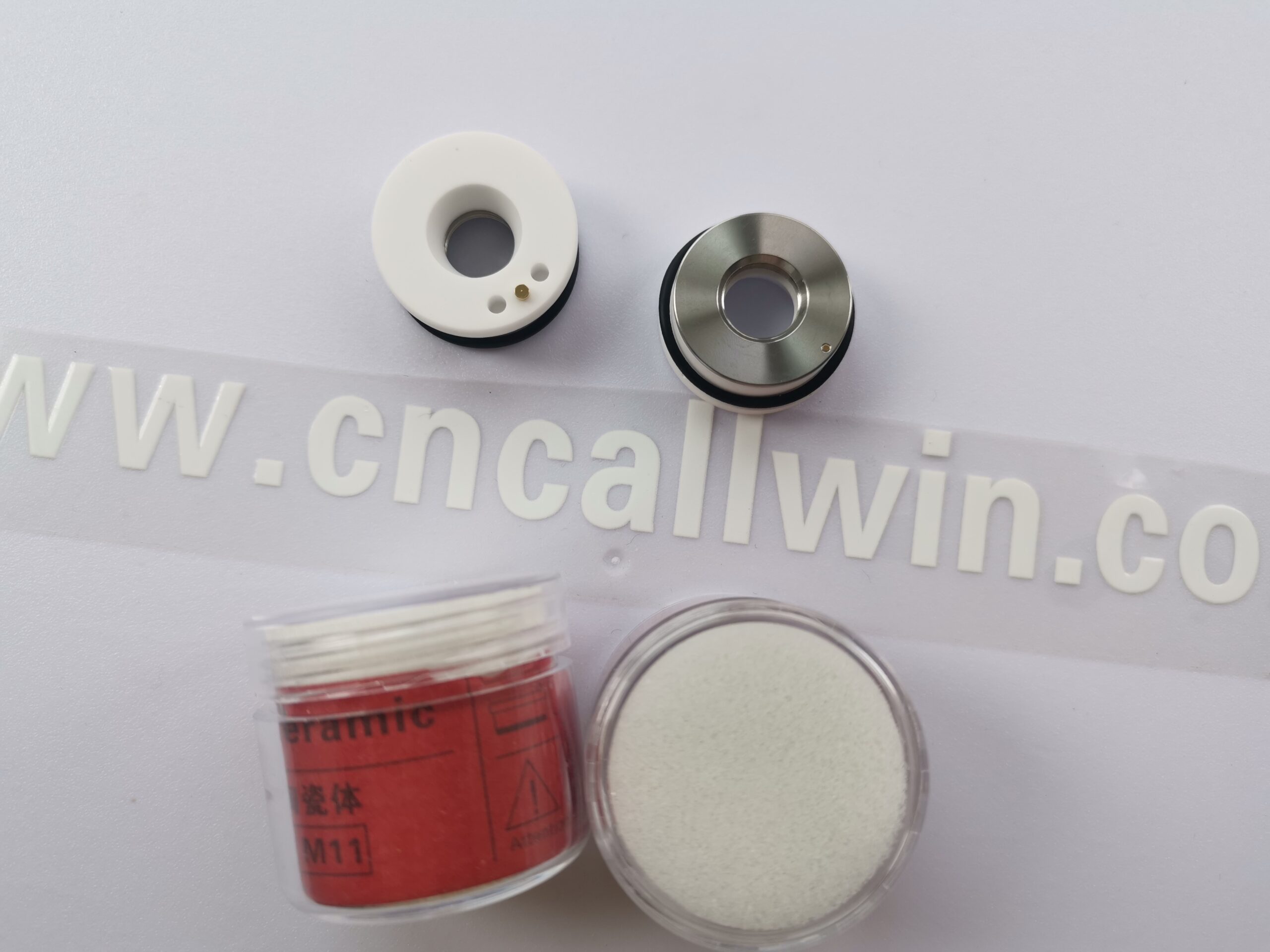

Welcome to our consumables category page for laser cutting machines and handheld laser welding machines. We take pride in offering a wide range of high-quality spare parts that go beyond just lenses and nozzles. We also provide top-of-the-line ceramic rings, focusing/collimating lens holders.

Ceramic rings are essential components known for their heat resistance and excellent thermal insulation properties. They are designed to optimize the cutting process, ensuring efficient and precise performance. With our ceramic rings, you can achieve consistent and reliable results, enhancing the overall quality of your projects.

Our focusing/collimating lens holder is specifically designed to securely hold and position the focusing/collimating lens in your laser system. Crafted with precision and reliability in mind, our holder ensures stable alignment, allowing for optimal focusing of the laser beam. Experience enhanced control and accuracy in your laser cutting or welding applications with our high-quality focusing lens holder.

Explore our diverse range of consumables, including protective mirror, focusing lens, collimating lens, ceramic rings, and focusing/collimating lens holders, to elevate the performance of your laser cutting and welding processes. Invest in our high-quality consumables and experience exceptional results in your projects.

Specifications of Ceramic Rings and Focusing / Collimating Lens Holders

In the world of laser cutting machines and handheld laser welding machines, ceramic rings and focusing/collimating lens holders are key consumables that play a critical role in achieving precise and efficient operations. The following is an overview of the specifications of ceramic rings and focusing/collimator lens holders, including their material composition and applications in cutting different materials.

Ceramic Rings:

Material Composition: Our ceramic rings are composed of high-grade ceramic materials known for their exceptional heat resistance and thermal insulation properties. These rings are carefully engineered to withstand the intense temperatures generated during laser cutting processes.

Applications: Ceramic rings are primarily used in laser cutting machines for cutting a wide range of materials. They are particularly effective in applications involving high-temperature materials like metals, alloys, and composites. The excellent thermal insulation of ceramic rings ensures efficient energy transfer and precise cuts, resulting in high-quality outcomes.

Focusing/Collimating lens Holders:

Material Composition: Our focusing/collimator lens holders are constructed using durable and heat-resistant materials such as stainless steel or aluminum alloys. These materials ensure long-lasting performance and stability during the laser cutting or welding process.

Applications: Focusing/collimating lens holders are essential components in laser systems, primarily used for holding and positioning focusing lenses or collimating lenses. These holders enable the precise focusing of the laser beam, allowing for accurate and controlled cutting or welding of various materials. They are commonly utilized in applications involving metals, plastics, glass, ceramics, and other materials commonly encountered in industrial or manufacturing processes.

Welcome to explore our range of ceramic rings and focusing/collimating lens holders. We are delighted to assist you with your procurement needs. If you have any questions or require further information, please do not hesitate to contact us. Our dedicated team is ready to assist you and provide personalized assistance based on your specific requirements. We are committed to delivering high-quality products and excellent customer service. Feel free to reach out to us at any time.

Application industry

- Automotive Industry: Both laser cutting and laser welding technologies find extensive use in the automotive industry. Laser cutting is employed for precise cutting of metal components, while laser welding is utilized for joining or repairing metal parts, such as body panels, chassis, exhaust systems, and engine components.

- Aerospace Industry: The aerospace industry relies on laser cutting for intricate shaping of various materials, including metals and composites, used in the manufacturing of aircraft components. Laser welding is also used for joining metal parts and performing repairs on aerospace structures.

- Metal Fabrication and Manufacturing: Laser cutting machines are widely utilized in metal fabrication and manufacturing industries for cutting and profiling various metals, while laser welding machines are used for joining metal parts, such as seams, joints, and complex assemblies, with high precision and strength.

- Electronics and Semiconductor: Both laser cutting and welding technologies play important roles in the electronics and semiconductor industries. Laser cutting is used to process materials for PCBs (printed circuit boards) and other electronic components, while laser welding is employed for precise joining of small electronic parts.

- Medical Devices: The medical device industry utilizes both laser cutting and laser welding for manufacturing and assembling intricate and precise medical devices and implants. Laser cutting is used for cutting and shaping components, while laser welding is employed for joining and sealing parts.

- Jewelry and Watchmaking: Laser cutting and welding machines are commonly employed in the jewelry and watchmaking industry for creating intricate designs, engraving, and precise joining of metal components.

Applicable people

- Professionals in the Manufacturing and Engineering Industry: This includes professionals such as mechanical engineers, industrial designers, manufacturing technicians, and quality control specialists who work with laser cutting and welding machines in industries like automotive, aerospace, metal fabrication, and electronics.

- Artisans and Designers: Artists, craftsmen, and designers who work with laser cutting machines for creative applications such as creating intricate designs, personalized items, and custom artwork on various materials like wood, acrylic, and leather.

- Researchers and Academics: Scientists, researchers, and educators in the field of optics, laser technology, and material sciences who utilize laser consumables for their experiments, studies, and educational purposes.

- Entrepreneurs and Small Business Owners: Individuals who operate small businesses or startups that leverage laser cutting machines for prototyping, product development, and manufacturing of various products across different industries.

- Jewelry and Watchmaking Professionals: This includes jewelers, goldsmiths, watchmakers, and jewelry designers who use laser consumables for precise cutting, engraving, and welding of metals in the creation of fine jewelry and watches.

- Medical Device Manufacturers and Healthcare Professionals: Professionals involved in the production of medical devices and implants, as well as medical practitioners who utilize laser technology in their treatment procedures, may require laser consumables for cutting, welding, and marking medical components.

- Architects and Interior Designers: Professionals in the architecture and design industry who rely on laser cutting machines for creating intricate architectural models, prototypes, decorative elements, and precise cuts in materials like wood, acrylic, and stone.

- Packaging and Labeling Industry: Professionals in the packaging and labeling industry who use laser cutting machines for custom packaging designs, prototype development, and precision cutting of materials like paper, cardboard, and films.

- Fashion and Textile Industry: Professionals in fashion design, garment manufacturing, and textile production who use laser cutting machines for intricate fabric cutting, pattern making, and engraving.

Applicable brands

Our laser consumables are compatible with renowned brands like Suplasercut, Relfar, Bodor, WSX, Empower and more. With high-quality materials and precision manufacturing, our consumables ensure optimal performance and durability. Whether you require laser cutting lenses, laser welding nozzles, or other laser-related accessories, our products provide a cost-effective solution without compromising on quality. Experience reliable and efficient laser operations with our laser consumables, tailored to meet the needs of professionals in the industry.

Caution and Maintenance

- Safety Precautions:Always follow the manufacturer’s guidelines and recommendations for handling and using laser consumables. Ensure that the laser machine is turned off and disconnected from the power source before performing any maintenance or replacing consumables.

- Cleaning:Regularly clean laser consumables to remove debris or residue that can affect their performance. Use suitable cleaning solutions and lint-free materials. Avoid using abrasive materials or harsh chemicals that may damage the consumables. Ensure that consumables are fully dry before reinstallation to prevent contamination or damage to the laser machine.

- Inspections and ReplacementsFrequently inspect laser consumables for signs of wear, damage, or deterioration. Replace any consumables that show visible signs of degradation. Check for proper alignment and positioning of consumables to maintain accurate laser beam focus and performance. Keep spare consumables readily available to minimize downtime and maintain the continuous operation of the laser machine.

- Proper Storage:Store laser consumables in a clean and dry environment to prevent moisture, dust, or other contaminants from affecting their performance. Follow the recommended storage conditions specified by the manufacturer, such as temperature and humidity levels. Ensure consumables are stored away from any chemicals or substances that might compromise their integrity.

- Professional Maintenance:Schedule regular maintenance and inspections of the laser machine by trained technicians to ensure optimal performance and safety. Consult with the laser machine manufacturer or authorized service centers for specific maintenance procedures and recommendations.

Following these cautions and maintenance practices will help ensure that your laser consumables operate effectively and safely, prolonging their lifespan and maintaining the quality of your laser processes.

Caution and Maintenance

When using laser lenses, it’s important to exercise caution to ensure safety and maintain their performance. Here are some precautions and maintenance tips for laser lenses:

- Safety Precautions: Follow proper laser safety protocols and guidelines in your work environment. Avoid directly looking into laser beams or pointing them at people or reflective surfaces.

- Replacement and Handling: When removing the lens, hold the circumference of the lens with your hand and do not touch the surface of the lens. Once the lens is contaminated, it needs to be replaced in a timely manner, otherwise it will affect cutting efficiency and even damage the machine.

- Storage and Protection: Store laser lenses in a clean, dry, and dust-free environment to prevent contamination. Use lens caps or protective covers to shield lenses when not in use. Avoid exposing lenses to extreme temperatures or direct sunlight, as this can affect their performance.

- Regular Inspection: Inspect lenses for any signs of damage, scratches, or deterioration before each use. If you notice any damage or degradation, consult us for guidance on repair or replacement.

- Calibration and Alignment: Periodically calibrate and align laser lenses according to our recommendations or specific application requirements. If you’re not familiar with calibration procedures, consult us for assistance.

By following these precautions and performing regular maintenance, you can ensure the longevity and proper functioning of your laser lenses, while also prioritizing safety in laser-related activities.

In case you have any inquiries or need further assistance, our team is readily available to support you. Trust us for all your laser lens and mirror requirements, and let us be your partner in achieving outstanding results in laser cutting and welding operations.