Lincoln

We offer a wide range of Lincoln Electric plasma consumables, with a special focus on the Spirit, Tomahawk, Flex-Cut and Pro-Cut series. As a leading supplier, we are committed to providing you with high-quality, reliable, and innovative solutions.

Whether you work in metal fabrication, construction, automotive manufacturing, or any other industry, our products are designed to meet your cutting needs. The Spirit series delivers outstanding cutting performance, ensuring precise, fast, and clean cutting results. Meanwhile, the Pro-cut series is tailored to handle high-strength cutting requirements, allowing you to tackle thicker metal plates.

Our plasma consumables are known for their exceptional durability and wear resistance, catering to various materials such as steel, stainless steel, and aluminum. Whether it’s in metal structures, architectural metalwork, or automotive production, our products satisfy your cutting demands by delivering efficient, accurate, and clean cutting performance.

With our team’s extensive experience and expertise, we provide professional advice and support to assist you in selecting the right consumables and solutions. Our goal is to enhance your work efficiency, reduce costs, and deliver excellent cutting quality.

Feel free to explore our website to learn more about LINCOLN Spirit and Procut series plasma consumables. If you have any questions or require further assistance, our team is ready to help.

The main systems and toches of Lincoln

Lincoln flexcut, Lincoln Pro-Cut, The Lincoln Tomahawk, Lincoln spirit II systems and toches LC100M/105M/125M, PCT-20/60/80/125, LC25/40/65/105.

Correspondingly, there are various types of consumables for Lincoln electric plasma cutting systems and welding torch series.

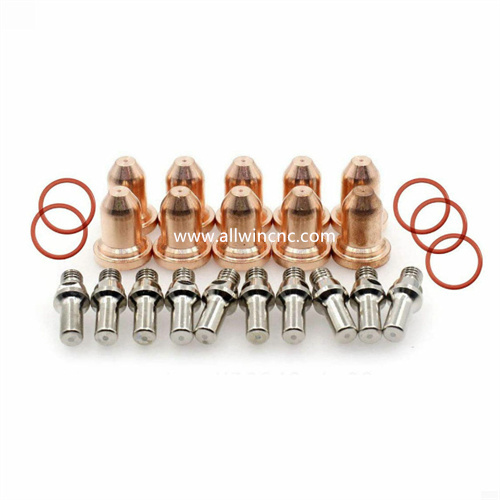

Don’t worry! Allwin provides a comprehensive selection of LINCOLN plasma consumables, including electrodes, nozzles, shields, swirl rings, and more. They offer various models and sizes to cater to different plasma cutting applications, giving you the flexibility to choose the most suitable consumables for your needs.

Specifications of Lincoln Electric plasma Consumables

Electrode:

Material: Electrodes are typically made of copper alloys or other high-temperature resistant materials.

Function: It transmits the electrical current and helps maintain the stability of the plasma cutting process.

Usage: Electrodes are used in both manual and mechanized cutting applications. And they are suitable for various materials.

Swirl ring:

Material: Insulating materials such as ceramic or plastic, which can withstand high temperatures and provide electrical insulation.

Function:creating and stabilizing the plasma arc. It helps control the gas flow and provides a pathway for the electrode and nozzle assembly.

Usage: To improved cutting performance and are suitable for various materials and thicknesses.

Retaining cap:

Material: Usually made of copper or copper alloys.

Function: Holding the electrode, nozzle, and other consumables together, providing structural support and electrical connections.

Usage: maintaining the alignment and stability of the plasma arc.

Nozzle:

Material: Commonly made of copper or copper alloys.

Function: To accelerate and shape the plasma gas flow, creating a focused and efficient plasma arc. It also protects the surrounding components from excessive heat.

Usage: cutting a wide range of materials, including steel, stainless steel, aluminum, and other conductive metals. Nozzles should be regularly checked and replaced to maintain optimal cutting performance.

Front Isolator:

Material: Front isolators are typically made of ceramic or other insulating materials, ensuring electrical insulation and thermal protection.

Function: Preventing short circuits and acting as a heat barrier, protecting the torch body from excessive heat.

Usage: To maintain a consistent arc gap and improving the longevity of the torch. They are suitable for various cutting applications and materials.

Shield cap:

Material: Commonly made of durable materials like copper or brass.

Function: To protect the nozzle from molten metal spatter and excessive heat. It also helps maintain the desired standoff distance between the torch and the workpiece.

Usage: For various cutting applications and materials, ensuring efficient and controlled cutting operations.

Drag cap:

Material: Typically made of robust materials such as copper or brass.

Function: For drag cutting or template following applications. It provides stability and control during cutting operations.

Usage: Drag caps are used when the torch is dragged along the cutting surface rather than being held perpendicular to it. They are suitable for various materials and thicknesses, ensuring precise and controlled cutting movements.

Buying Guide of Lincoln Electric plasma Consumables

Electrode: specific model and compatibility. Look for electrodes made of high-quality materials. Purchasing in bulk can be a cost-effective option. At Allwin, we offer electrode bundles and multipacks at a discounted price.

Swirl ring: Material and durability, select the materials contribute to longer lifespan and consistent performance. Consider swirl rings with design features that enhance cutting efficiency and stability.

Nozzle: Select the nozzle size that matches your desired cutting applications and material thicknesses. Choose nozzles made from high-quality materials like copper or copper alloys.

Retaining cap: Ensure that the retaining cap is the appropriate size for your electrode and nozzle combination. Look for retaining caps made from durable materials like copper or brass for longevity and reliable performance.

Front Isolator: Verify the compatibility and specifications. Choose material and insulation properties made from high-quality ceramic or insulating materials.

Shield cap: Verify the compatibility and specifications. Look for shield caps made from robust materials such as copper or bras

Drag cap: Consider the compatibility and Longevity, and as much as possiblepurchase drag caps from trusted and reputable suppliers.

At Allwin, you can see kinds of kits! These kits can be convenient and cost-effective, especially when you require multiple consumables simultaneously. Choose us to bring you efficient cutting efficiency and enhance your cutting experience!

Application industry

- Manufacturing and Fabrication: Lincoln Electric plasma consumables play a crucial role in the manufacturing and fabrication industry. They are commonly employed for cutting and shaping metal sheets and plates, creating precise and clean cuts. Industries such as automotive, aerospace, and shipbuilding heavily rely on plasma cutting for their fabrication processes.

- Construction: In the construction industry, Lincoln Electric plasma consumables are essential for activities like HVAC installation, metal structure construction, and pipeline installation. The versatility of plasma cutting allows for efficient and accurate cutting of various materials like steel, aluminum, and stainless steel, meeting the stringent requirements of construction projects.

- Maintenance and Repair: Plasma cutting is frequently used in maintenance and repair operations across industries. Lincoln Electric plasma consumables enable efficient cutting and removal of damaged or worn-out parts for repair or replacement. Whether it’s equipment repair, pipe cutting, or metal restoration, these consumables ensure precise and reliable cutting performance.

- Art and Decorative Work: Plasma cutting has found a place in the art and decorative industry, where intricate designs and patterns are crafted from metal. Lincoln Electric plasma consumables help artists and craftsmen create detailed and precise cuts in metal sheets, allowing for the creation of custom artwork, signs, ornaments, and other decorative pieces.

- Metal Recycling: Plasma cutting is also integral to the metal recycling industry. Lincoln Electric plasma consumables enable the efficient dismantling and processing of various metal items, maximizing material recovery and facilitating the recycling process.

Regardless of the industry, Lincoln Electric plasma consumables are trusted for their quality and precision, making them a valuable asset in a wide range of applications.

Applicable people

- Home Improvement: Plasma cutting using Lincoln Electric plasma consumables allows individuals to undertake home improvement projects with ease. Whether it’s cutting metal for DIY furniture, creating custom metal designs for home decor, or renovating outdoor spaces, plasma cutting provides precise and efficient results, empowering people to enhance their living environments.

- Automotive Enthusiasts: People passionate about automotive customization and restoration can rely on Lincoln Electric plasma consumables for their projects. Plasma cutting enables them to accurately cut and modify metal parts, fabricate custom body panels, and create unique designs for vehicle customization. This application allows automotive enthusiasts to personalize their vehicles and showcase their creativity.

- Artists and Sculptors: Artists and sculptors appreciate the versatility of plasma cutting for their creative endeavors. Lincoln Electric plasma consumables offer the ability to cut intricate shapes and designs in metal, allowing artists to bring their ideas to life with precision. Sculptors can create stunning metal sculptures with ease, adding a unique touch to public spaces or personal art collections.

- DIY Enthusiasts: DIY enthusiasts and hobbyists can benefit from Lincoln Electric plasma consumables to complete a wide range of projects. Whether it’s building metal structures, fabricating garden ornaments, or constructing metal artwork, plasma cutting enables individuals to achieve professional-quality results in their DIY endeavors.

- Metalworking Professionals: Professionals in metalworking industries, such as welders and fabricators, rely on Lincoln Electric plasma consumables for their daily work. These consumables ensure consistent and reliable performance, allowing professionals to efficiently cut and shape metal materials, meet project deadlines, and deliver high-quality results.

The application of Lincoln Electric plasma consumables empowers individuals to undertake various projects, unleash their creativity, and achieve desired outcomes efficiently and effectively.

Whether you are a professional operator or an amateur user, Allwin always look forward to communicating and exchanging ideas with you!

Applicable brands

Our laser lenses are compatible with cutting torches of Bodor, WSX, Empower, and more. These lenses have been carefully designed to deliver exceptional performance while maintaining a high cost-effectiveness ratio.

We understand the importance of achieving both quality and affordability in your laser cutting processes. Our laser lenses offer superior optical properties, ensuring excellent beam focus and beam quality. This allows for precise and efficient cutting operations, resulting in clean and accurate cuts.

In addition to their compatibility and performance, our laser lenses also provide the flexibility of customization. We recognize that each laser system may have unique requirements, and our team is ready to collaborate with you to create custom lenses that meet your specific needs. Whether it’s a specific focal length, beam diameter, or any other parameter, we can tailor the lenses to suit your machine and application.

With our laser lenses, you can confidently enhance the capabilities of your Boder, WSX, Empower, or other cutting torches. They offer a winning combination of compatibility, cost-effectiveness, and customization, helping you achieve optimal results in your laser cutting operations.

Caution and Maintenance

- Safety Precautions: Always prioritize safety when using Lincoln Electric plasma consumables. Wear appropriate personal protective equipment (PPE), such as safety glasses, gloves, and flame-resistant clothing, to protect against sparks, heat, and metal debris. Follow all safety guidelines provided by Lincoln Electric and adhere to local safety regulations.

- Proper Handling: Handle plasma consumables with care to avoid damage. Avoid dropping or mishandling the consumables, as they can be delicate and sensitive. Always store them in a clean, dry, and protected environment to prevent corrosion or contamination.

- Regular Inspections: Before each use, inspect the consumables for any signs of wear, damage, or distortion. Replace any worn-out or damaged parts immediately. Regularly check the connections, cables, and torch for integrity and ensure proper grounding to maintain electrical safety.

- Cleaning and Maintenance: Clean the consumables regularly to remove debris, slag, and metal build-up. Use appropriate cleaning solutions recommended by Lincoln Electric. Inspect and replace O-rings, seals, and other wear parts as necessary to maintain optimal performance.

- Proper Installation: Follow the manufacturer’s instructions for correct installation of plasma consumables. Ensure the consumables are securely installed and aligned for efficient cutting performance. Improper installation can lead to poor cut quality, premature wear, and potential safety hazards.

- Cooling and Drying: Allow the plasma consumables to cool down adequately before handling or storage. Moisture can negatively impact performance and longevity, so ensure the consumables are completely dry before using or storing them.

- Professional Servicing: In case of any technical issues or if performance deteriorates, consult a qualified technician or contact Lincoln Electric’s customer support for guidance. Professional servicing and maintenance are important to ensure the long-term reliability and performance of the plasma consumables.

Following these cautionary measures and maintenance practices can help prolong the lifespan of Lincoln Electric plasma consumables, maintain optimal cutting performance, and ensure safe usage.

Thank you for choosing us. Let’s together improve your cutting experience!