Laser Lenses

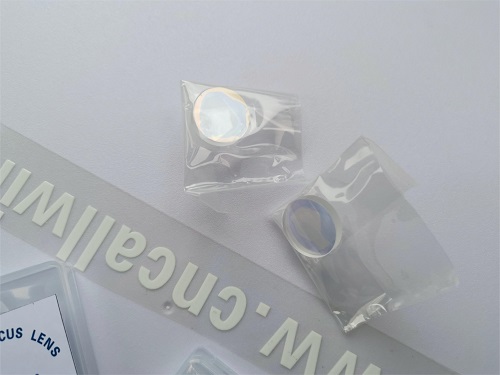

Welcome to our website! In this section, we will introduce you to the essential optical components used in laser cutting machines and handheld laser welding machines. These components include protective mirrors, focusing lenses, and collimating lenses.

Protective Mirrors:

Protective mirrors are crucial in laser systems as they act as a barrier between the laser beam and the surrounding environment. These lenses are typically made from durable materials that can withstand the intense energy and power of the laser beam. They serve to protect the more delicate optical components from debris, splatter, and other potential hazards, ensuring the longevity and reliability of the laser system.

Focusing Lenses:

Focusing lenses play a critical role in laser cutting machines. They are specifically designed to concentrate the laser beam to a precise focal point. These lenses allow for high energy density at the focal point, enabling precise and efficient material cutting. Focusing lenses are typically transparent and made from optical-grade materials to minimize energy loss and maximize beam quality.

Collimating Lenses:

Collimating lenses are utilized in both laser cutting machines and handheld laser welding machines. These lenses help control the divergence of the laser beam by making it more parallel or collimated. They assist in achieving a consistent and stable laser beam profile, ensuring optimal performance and quality in laser processes. Collimating lenses are usually made from materials with high transmission properties to minimize energy loss and maintain beam integrity.

It is important to note that the selection of lenses for laser systems depends on factors such as laser power, wavelength, and specific application requirements. Choosing the appropriate lens components is crucial to achieving the desired results in laser cutting and welding operations.

Specifications of Laser Lenses

Laser cutting machines are widely used in various industries for precision cutting and engraving tasks. Three essential components of a laser cutting system are the protective mirror, focusing lens, and collimating lens. The following are the specifications of these components, including their material composition and usage for cutting different materials.

Protective Mirror:

Material: Typically made from high-quality fused silica or quartz.

Function: The protective mirror is designed to reflect and redirect the laser beam, protecting the more delicate components of the laser cutting system.

Usage: It is primarily used to shield the beam delivery path from damage caused by debris, gases, or spatter generated during the cutting process.

Focusing Lens:

Material: Commonly made from zinc selenide (ZnSe) or germanium (Ge).

Function: The focusing lens converges the laser beam to a small focal point, which increases the power density for precise cutting.

Usage: It enables the laser beam to attain high energy density and efficient cutting for materials such as metals, plastics, wood, and composites.

Collimating Lens:

Material: Typically composed of BK7 or other optical glasses.

Function: The collimating lens helps to convert the diverging laser beam into a parallel beam, improving the cutting performance.

Usage: It is commonly used in laser cutting machines to achieve uniform and consistent cutting results, especially for materials like acrylic, glass, and fabrics.

It’s important to note that the specific specifications of these components can vary depending on the laser cutting system’s manufacturer, intended application, and desired cutting parameters. If you have any questions, please contact us and we are happy to provide you with a purchasing guide.

Buying Guide of laser lenses

Here’s everything you need to know about purchasing protective mirrors, focusing lenses, and collimating lenses.

Protective Mirrors: Safeguard your laser system with our high-quality, wavelength-specific protective mirrors. Choose from our durable options to ensure optimal performance and safety.

Focusing Lenses: Enhance precision and control with our focusing lenses. Consider factors like lens material, focal length, and spot size requirements to achieve optimal results.

Collimating Lenses: Achieve the desired beam divergence or convergence with our collimating lenses. Select the right lens for your laser wavelength and desired beam characteristics.

At Allwin, we prioritize quality and performance, offering a wide range of lenses to meet your needs. Trust our expertise and discover the perfect lenses for your laser system. Experience superior performance and reliability. Explore our selection today!

Application industry

Laser lenses find application in a wide range of industries where laser systems are utilized. Here are some key industries where laser lenses are commonly used:

- Manufacturing and Industrial Sector: Laser lenses play a crucial role in various manufacturing processes such as laser cutting, welding, marking, and engraving. These lenses ensure precise focusing and shaping of the laser beam, resulting in accurate and efficient material processing.

- Medical and Healthcare: Laser lenses are utilized in medical applications such as laser surgery, dermatology, ophthalmology, and dental procedures. They help deliver precise and controlled laser energy for therapeutic and diagnostic purposes.

- Research and Development: Laser lenses are extensively used in research laboratories for scientific experiments, spectroscopy, microscopy, and laser beam analysis. They enable researchers to manipulate and control laser beams for accurate measurements and analysis.

- Electronics and Semiconductor Industry: Laser lenses are employed in processes like PCB manufacturing, microelectronics assembly, and semiconductor wafer fabrication. They play a vital role in laser-based alignment, surface modification, and precision drilling.

- Defense and Aerospace: Laser lenses are utilized in defense and aerospace applications for laser targeting, range finding, and missile guidance. They ensure accurate laser beam delivery and help achieve high-precision targeting.

- Automotive Industry: Laser lenses are used in automotive production lines for laser cutting, welding, and marking applications. They enable precise and efficient manufacturing processes that enhance product quality and productivity.

- Communication and Telecommunication: Laser lenses are employed in the field of fiber optics and telecommunications where lasers are used for signal transmission, amplification, and routing. These lenses aid in shaping and directing laser beams within optical fiber networks.

- Art and Entertainment: Laser lenses play a crucial role in laser shows, concerts, and artistic displays. They help create captivating laser patterns, shapes, and visual effects for entertainment purposes.

The versatility and precision of laser technologies make them invaluable tools in various professional fields, contributing to advancements and innovation across industries

Applicable people

Laser lenses are essential for a diverse range of individuals and professionals who work with laser systems.

Engineers, technicians, and researchers in fields such as manufacturing, healthcare, and scientific research rely on laser lenses to optimize laser system performance for tasks like cutting, welding, and measurement. Medical professionals utilize laser lenses for precise laser energy delivery in surgeries, dermatology, ophthalmology, and dentistry.

Manufacturing professionals in industries like automotive, aerospace, and electronics benefit from laser lenses for laser-based processes like cutting, marking, and quality control.

Artists and performers in the entertainment industry use laser lenses to create captivating laser shows and visual effects.

Telecommunication professionals and fiber optics experts employ laser lenses to shape and manipulate laser beams for efficient signal transmission.

Additionally, hobbyists and enthusiasts interested in laser technology can explore various applications with the help of laser lenses.

Regardless of your level of expertise, laser lenses can be beneficial in enabling precise control and manipulation of laser beams for various applications.

Whether you’re a professional or an enthusiast, laser lenses offer versatility and utility in working with laser systems.

Applicable brands

Our laser lenses are compatible with cutting torches of Bodor, WSX, Empower, and more. These lenses have been carefully designed to deliver exceptional performance while maintaining a high cost-effectiveness ratio.

We understand the importance of achieving both quality and affordability in your laser cutting processes. Our laser lenses offer superior optical properties, ensuring excellent beam focus and beam quality. This allows for precise and efficient cutting operations, resulting in clean and accurate cuts.

In addition to their compatibility and performance, our laser lenses also provide the flexibility of customization. We recognize that each laser system may have unique requirements, and our team is ready to collaborate with you to create custom lenses that meet your specific needs. Whether it’s a specific focal length, beam diameter, or any other parameter, we can tailor the lenses to suit your machine and application.

With our laser lenses, you can confidently enhance the capabilities of your Boder, WSX, Empower, or other cutting torches. They offer a winning combination of compatibility, cost-effectiveness, and customization, helping you achieve optimal results in your laser cutting operations.

Caution and Maintenance

When using laser lenses, it’s important to exercise caution to ensure safety and maintain their performance. Here are some precautions and maintenance tips for laser lenses:

- Safety Precautions: Follow proper laser safety protocols and guidelines in your work environment. Avoid directly looking into laser beams or pointing them at people or reflective surfaces.

- Replacement and Handling: When removing the lens, hold the circumference of the lens with your hand and do not touch the surface of the lens. Once the lens is contaminated, it needs to be replaced in a timely manner, otherwise it will affect cutting efficiency and even damage the machine.

- Storage and Protection: Store laser lenses in a clean, dry, and dust-free environment to prevent contamination. Use lens caps or protective covers to shield lenses when not in use. Avoid exposing lenses to extreme temperatures or direct sunlight, as this can affect their performance.

- Regular Inspection: Inspect lenses for any signs of damage, scratches, or deterioration before each use. If you notice any damage or degradation, consult us for guidance on repair or replacement.

- Calibration and Alignment: Periodically calibrate and align laser lenses according to our recommendations or specific application requirements. If you’re not familiar with calibration procedures, consult us for assistance.

By following these precautions and performing regular maintenance, you can ensure the longevity and proper functioning of your laser lenses, while also prioritizing safety in laser-related activities.

In case you have any inquiries or need further assistance, our team is readily available to support you. Trust us for all your laser lens and mirror requirements, and let us be your partner in achieving outstanding results in laser cutting and welding operations.