Hypertherm-MAXPro200 consumables

Hypertherm-MAXPro200 consumables China factory

Hypertherm-MAXPro consumables feature advanced technology and superior quality, ensuring outstanding results and extended product lifespan.

With their precise engineering and durability, MAXPro consumables deliver exceptional cut quality, increased productivity, and reduced downtime.

These consumables are easy to install and compatible with a wide range of Hypertherm-MAXPro plasma cutting systems.

Whether you’re working with mild steel, stainless steel, or non-ferrous metals, MAXPro consumables provide optimal performance and reliable operation.

Upgrade your cutting process with Hypertherm-MAXPro consumables for superior efficiency and outstanding cutting results.

MAXpro200 consumables – mechanized torch

Mild steel/stainless steel/aluminum consumables

| Process | Current | Shield | Shield cap | Nozzle | Swirl ring | Electrode |

| Air | 50 A | 220532 | 220936 | 220890 | 220529 | 220528 |

| 220935 without tab | ||||||

| 130 A | 220536 | 220936 | 220892 | 220488 | 220487 | |

| 220935 without tab | ||||||

| 200 A | 420045 | 220936 | 420044 | 220488 | 220937 | |

| 220935 without tab |

Mild steel consumables

| Process | Current | Shield | Shield cap | Nozzle | Swirl ring | Electrode |

| O2 | 50 A | 220532 | 220936 | 220891 | 220529 | 220528 |

| 220935 without tab | ||||||

| 130 A | 220491 | 220936 | 220893 | 220488 | 220487 | |

| 220935 without tab | ||||||

| 130 A CCW | 220491 | 220534 | 220893 | 420796 | 220487 | |

| 220533 without tab | ||||||

| 200 A | 220832 | 220936 | 220831 | 220834 | 220937 | |

| 220935 without tab | ||||||

| 200 A CCW | 220832 | 220534 | 220831 | 420795 | 220937 | |

| 220533 without tab |

Stainless steel/aluminum consumables

| Process | Current | Shield | Shield cap | Nozzle | Swirl ring | Electrode |

| N2 | 130 A | 220536 | 220936 | 220892 | 220529 | 020415 |

| 220935 without tab | ||||||

| 200 A | 420045 | 220936 | 420044 | 220529 | 020415 | |

| 220935 without tab |

Mild steel extreme bevel consumables

| Process | Current | Shield | Shield cap | Nozzle | Swirl ring | Electrode |

| Air | 130 A | 420735 | 220936 | 420829 | 220488 | 420824 |

| 220935 without tab | ||||||

| 200 A | 420737 | 220936 | 420734 | 220488 | 420732 | |

| 220935 without tab | ||||||

| O2 | 130 A | 420735 | 220936 | 420828 | 220529 | 420824 |

| 220935 without tab | ||||||

| 200 A | 420737 | 220936 | 420733 | 220488 | 420732 | |

| 220935 without tab |

MAXPRO200 consumables – manual torch

Mild steel/stainless steel/aluminum consumables

| Process | Current | Shield | Shield cap | Nozzle | Swirl ring | Electrode |

| Air | 50 A | 420063 | 220935 | 220890 | 220529 | 220528 |

| 130 A | 420061 | 220935 | 220892 | 220488 | 220487 | |

| 200 A | 420058 | 220935 | 420044 | 220488 | 220937 | |

| 200 A gouging | 420067 | 420793 | 420066 | 220488 | 220937 |

Mild steel consumables

| Process | Current | Shield | Shield cap | Nozzle | Swirl ring | Electrode |

| O2 | 50 A | 420063 | 220935 | 220891 | 220529 | 220528 |

| 130 A | 420062 | 220935 | 220893 | 220488 | 220487 | |

| 200 A | 420059 | 220935 | 220831 | 220834 | 220937 | |

| 200 A gouging | 420067 | 420793 | 420066 | 220834 | 220937 |

Mild steel extreme bevel consumables

| Process | Current | Shield | Shield cap | Nozzle | Swirl ring | Electrode |

| Air | 130 A | 420735 | 220936 | 420829 | 220488 | 420824 |

| 220935 without tab | ||||||

| 200 A | 420737 | 220936 | 420734 | 220488 | 420732 | |

| 220935 without tab | ||||||

| O2 | 130 A | 420735 | 220936 | 420828 | 220529 | 420824 |

| 220935 without tab | ||||||

| 200 A | 420737 | 220936 | 420733 | 220488 | 420732 | |

| 220935 without tab |

MaxproTorchand consumables features

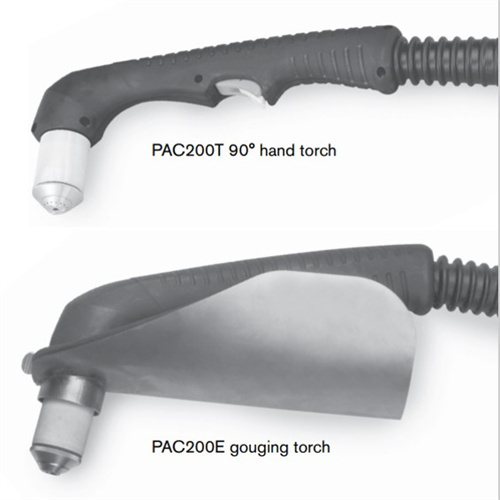

The Hypertherm MAX200 is a high-definition plasma cutting system renowned for its precision cutting, faster cutting speeds, versatility, ease of use, durability, and reliability. It utilizes the PAC200T/E torch assembly, a critical component that securely holds the consumables and efficiently delivers the plasma arc for accurate cuts. This torch assembly provides exceptional process flexibility, allowing for cutting, beveling, and marking of various metals.

To further enhance the performance of the MAX200 system, Hypertherm offers a range of high-quality consumables that improve cut quality, extend consumable life, and boost productivity. The Hypertherm Maxpro200 plasma consumables include the following components:

Nozzle:Hypertherm nozzles play a crucial role in focusing the plasma arc and surrounding gas to achieve clean and precise cuts. Nozzles with larger openings are suitable for gouging applications, while nozzles with smaller openings are better for fine, detailed work. The available nozzle options for the Maxpro200 system are 220890, 220891, 220893, and 220831.

Electrode: Electrodes are narrow pieces of copper containing hafnium, an excellent conductor of electricity. They receive electrical current from the cathode block inside the torch, focusing the charge through their tips to create an arc onto the workpiece. The available electrode options for the Maxpro200 system are 220528, 220487, and 220937.

Shield Cap: The shield cap is responsible for holding all the consumable parts of the torch together. This component endures extremely high temperatures, leading to wear and degradation over time. The available shield cap options for the Maxpro200 system are 220532, 220491, and 220832.

Swirl Ring: Swirl rings have a swirling action that stabilizes and shapes the plasma arc, resulting in a more concentrated and efficient cutting or welding process. The available swirl ring options for the Maxpro200 system are 220529, 220488, 420796, 220834, and 420795.

Retaining Cup: Similar to the shield cap, the retaining cup holds all the consumable parts of the torch together. It also experiences wear and degradation due to the high temperatures involved. The available retaining cup options for the Maxpro200 system are 220578 and 220490.

Shield Cup: The shield cup, also known as the shield cap, controls the flow of the shielding gas. It has specific openings or slots that regulate the gas flow and distribution, directly impacting the shape and size of the plasma arc. The available shield cup options for the Maxpro200 system are 220936 and 220935.

As a one-stop service provider, you offer genuine Hypertherm consumables to ensure optimal performance, compatibility, and extended lifespan for the Hypertherm MAX200 system with the PAC200 Plasma Arc Cutting torch model. By utilizing these recommended consumables, customers can achieve improved cut quality, increased productivity, and superior results in their plasma cutting operations

Related products

-

Hypertherm

Hypertherm Plasma Cutting Torch Body 428147 228716 420220 420221 Replacement

Rated 0 out of 5Read more